What is Real-Time Search in AI?

Learn how real-time search in AI works, its benefits for users and businesses, and how it differs from traditional search engines and static AI models.

Discover how real-time data and AI transform inventory management. Learn the data requirements, technologies, and best practices for modern e-commerce inventory systems.

Real-time inventory data refers to stock information that is continuously updated and immediately accessible as transactions occur throughout your supply chain. Unlike traditional inventory management systems that rely on periodic batch updates—often conducted daily, weekly, or even monthly—real-time data provides instantaneous visibility into stock levels, sales velocity, and warehouse movements across all locations and channels. Artificial intelligence amplifies the value of this real-time data by processing vast amounts of information simultaneously, identifying patterns, and generating actionable insights that would be impossible for human analysts to detect manually. When AI systems have access to continuously updated inventory information, they can make split-second decisions about stock allocation, demand forecasting, and reordering that directly impact your bottom line. This convergence of real-time data and AI technology has fundamentally transformed how modern e-commerce businesses manage their most critical operational asset: inventory.

To function effectively, AI-powered inventory systems require a comprehensive and continuous stream of data that goes far beyond simple stock counts. These systems need real-time stock level data from every warehouse, fulfillment center, and retail location, updated with each transaction; sales velocity metrics showing how quickly products move across different channels; demand pattern data including seasonal trends, promotional impacts, and customer behavior; supplier information such as lead times, reliability metrics, and capacity constraints; warehouse location data tracking exact bin locations and storage conditions; and historical transaction data spanning months or years to train machine learning models. The quality and completeness of this data directly determines the accuracy of AI predictions and the effectiveness of inventory optimization decisions.

| Data Element | Traditional Systems | AI-Powered Systems |

|---|---|---|

| Update Frequency | Daily/Weekly batches | Real-time (seconds) |

| Data Sources | Single warehouse system | Multiple integrated sources |

| Historical Data | 3-6 months | 2+ years |

| Demand Signals | Manual forecasting | Algorithmic pattern recognition |

| Supplier Data | Static information | Dynamic, real-time metrics |

| Accuracy Requirement | 85-90% | 98%+ |

| Processing Speed | Hours to days | Milliseconds |

Without this comprehensive data foundation, even the most sophisticated AI algorithms will produce unreliable predictions and suboptimal inventory decisions.

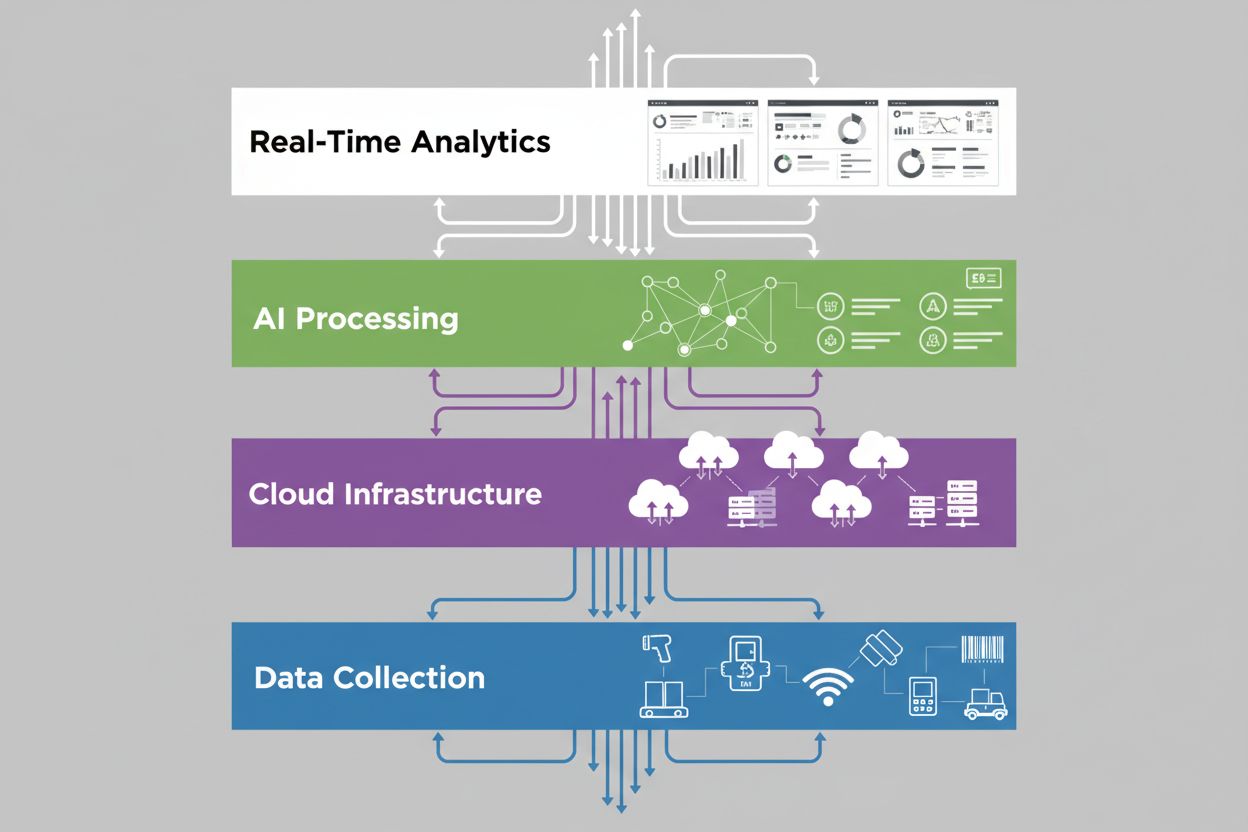

The infrastructure supporting real-time inventory data collection relies on several interconnected technologies working in concert. Internet of Things (IoT) devices—including smart sensors, weight scales, and environmental monitors—continuously track inventory movement and conditions within warehouses, transmitting data to central systems without human intervention. RFID (Radio Frequency Identification) tags attached to products or pallets enable instant identification and location tracking as items move through receiving, storage, picking, and shipping areas, dramatically reducing manual counting and improving accuracy. Barcode scanning systems remain fundamental to real-time tracking, with mobile devices and fixed scanners capturing transaction data at every touchpoint in the supply chain. Cloud-based inventory management platforms serve as the central nervous system, aggregating data from all these sources and making it instantly accessible to AI algorithms and human decision-makers. API integrations connect these systems with e-commerce platforms, marketplaces, ERP systems, and shipping carriers, ensuring that inventory data flows seamlessly across your entire business ecosystem. Together, these technologies create the foundation for the real-time data streams that power modern AI-driven inventory management.

Machine learning algorithms analyze historical sales data, seasonal patterns, promotional calendars, and external factors to predict future demand with remarkable accuracy—often improving forecast precision by 20-35% compared to traditional methods. These AI systems don’t simply extrapolate past trends; they identify complex relationships between variables that human analysts might miss, such as how weather patterns, competitor actions, or social media trends influence purchasing behavior. Predictive analytics enable businesses to anticipate stockouts before they occur, automatically triggering reorder processes when inventory levels are projected to fall below optimal thresholds. Inventory optimization algorithms continuously balance the competing demands of maintaining adequate stock to meet customer demand while minimizing carrying costs and the risk of obsolescence. By processing real-time sales data and adjusting predictions dynamically, AI systems can adapt to sudden market shifts—such as viral product trends or unexpected supply disruptions—far faster than traditional planning methods. The result is a dramatic reduction in both stockouts that damage customer satisfaction and overstock situations that tie up capital and warehouse space.

Managing inventory across multiple sales channels—your own e-commerce website, Amazon, eBay, Shopify, physical retail locations, and social commerce platforms—creates a complex synchronization challenge that real-time data solves elegantly. Without real-time inventory visibility, a product might show as “in stock” on your website while simultaneously being sold on Amazon, leading to the nightmare scenario of overselling and customer cancellations. Real-time data synchronization ensures that when a customer purchases an item on any channel, inventory levels are instantly updated across all platforms, preventing these costly errors.

Key benefits of real-time multi-channel inventory management:

This synchronization capability has become non-negotiable for any retailer operating across multiple channels.

Despite the tremendous potential of real-time inventory AI systems, organizations frequently struggle with data quality issues that undermine their effectiveness. Data silos—where inventory information exists in separate, disconnected systems—create inconsistencies and prevent AI algorithms from accessing the complete picture needed for accurate predictions. Integration challenges arise when legacy systems, third-party platforms, and new cloud solutions don’t communicate seamlessly, resulting in duplicate records, missing transactions, or conflicting information. Data inconsistencies such as different units of measurement, varying product classification schemes, or timing differences between when transactions occur and when they’re recorded can introduce significant errors into AI models. Data governance becomes critical; without clear policies for data entry standards, validation rules, and error correction procedures, even well-intentioned teams can inadvertently introduce inaccuracies that cascade through the entire system. Poor data quality directly translates to poor AI performance—a principle often summarized as “garbage in, garbage out”—meaning that even the most sophisticated algorithms cannot produce reliable inventory predictions from flawed or incomplete data.

Successfully implementing a real-time inventory data infrastructure requires a structured approach that balances technological capability with organizational readiness. First, conduct a comprehensive data audit to identify all existing data sources, assess current data quality, and determine what gaps exist between your current state and AI requirements. Second, select appropriate technologies based on your specific needs—cloud-based WMS platforms, IoT sensors, RFID systems, and integration middleware—ensuring they can scale as your business grows. Third, establish data governance frameworks that define standards for data entry, validation, security, and access control, preventing quality degradation as data flows through multiple systems. Fourth, implement robust API integrations that create seamless two-way communication between your inventory system, e-commerce platforms, ERP, and other business applications. Fifth, establish data pipelines that continuously extract, transform, and load data from source systems into your central data warehouse or data lake where AI algorithms can access it. Finally, invest in change management to ensure your team understands the new systems and processes, as technology alone cannot succeed without user adoption and proper training. Organizations that approach implementation methodically, rather than attempting to deploy everything simultaneously, achieve faster time-to-value and more sustainable results.

To justify the investment in real-time inventory AI systems and continuously improve their performance, organizations must track specific key performance indicators (KPIs) that measure both operational efficiency and business impact. Inventory accuracy rate—the percentage of physical stock that matches system records—should exceed 98% with real-time systems, compared to 85-90% with traditional approaches. Inventory turnover ratio measures how quickly inventory moves through your business; AI optimization typically increases this metric by 15-25%, freeing up capital for other investments. Stockout rate tracks the percentage of customer orders that cannot be fulfilled due to insufficient inventory; real-time AI systems typically reduce this by 30-40% through better demand forecasting. Forecast accuracy measures how closely predicted demand matches actual sales; improvements of 20-35% are common after implementing AI-powered systems. Order fulfillment time should decrease as real-time location data enables faster picking and packing; many organizations achieve 20-30% improvements. Carrying cost reduction reflects the financial benefit of holding less excess inventory while maintaining service levels. By monitoring these metrics consistently, you can demonstrate ROI, identify optimization opportunities, and continuously refine your real-time inventory AI system’s performance.

Real-time inventory data refers to stock information that is continuously updated and immediately accessible as transactions occur. It's critical for AI because these systems need current, accurate data to make split-second decisions about stock allocation, demand forecasting, and reordering that directly impact your business performance.

AI-powered inventory systems require comprehensive data including real-time stock levels from all locations, sales velocity metrics, demand patterns and seasonal trends, supplier information and lead times, warehouse location data, and historical transaction data spanning months or years to train machine learning models effectively.

Real-time data synchronization ensures that when a customer purchases an item on any channel, inventory levels are instantly updated across all platforms. This prevents the same product from being sold twice and eliminates the costly errors of overselling and customer cancellations.

Key challenges include data silos where inventory information exists in separate systems, integration difficulties between legacy and new platforms, data inconsistencies in measurement units or classification schemes, and the need for robust data governance policies to maintain accuracy throughout the system.

Track key performance indicators including inventory accuracy rate (should exceed 98%), inventory turnover ratio, stockout rate, forecast accuracy, order fulfillment time, and carrying cost reduction. These metrics demonstrate ROI and identify opportunities for continuous improvement.

Essential technologies include IoT devices for continuous monitoring, RFID tags for instant identification and location tracking, barcode scanning systems at every touchpoint, cloud-based inventory management platforms as the central system, and API integrations connecting all business systems seamlessly.

Machine learning algorithms analyze historical sales data, seasonal patterns, promotional calendars, and external factors to identify complex relationships that humans might miss. AI systems can improve forecast precision by 20-35% compared to traditional methods and adapt dynamically to sudden market shifts.

Organizations typically see 20-35% improvements in forecast accuracy, 30-40% reduction in stockout rates, 15-25% increase in inventory turnover, and 20-30% faster order fulfillment times. These improvements translate to reduced carrying costs, fewer lost sales, and significantly improved customer satisfaction.

AmICited tracks how AI systems like ChatGPT, Perplexity, and Google AI Overviews cite your inventory management solutions and real-time data platforms. Stay informed about your brand's presence in AI-generated content.

Learn how real-time search in AI works, its benefits for users and businesses, and how it differs from traditional search engines and static AI models.

Learn what Real-Time Content APIs are and how they provide AI systems with current content updates for time-sensitive information. Explore streaming protocols, ...

Discover real-time AI adaptation - the technology enabling AI systems to continuously learn from current events and data. Explore how adaptive AI works, its app...