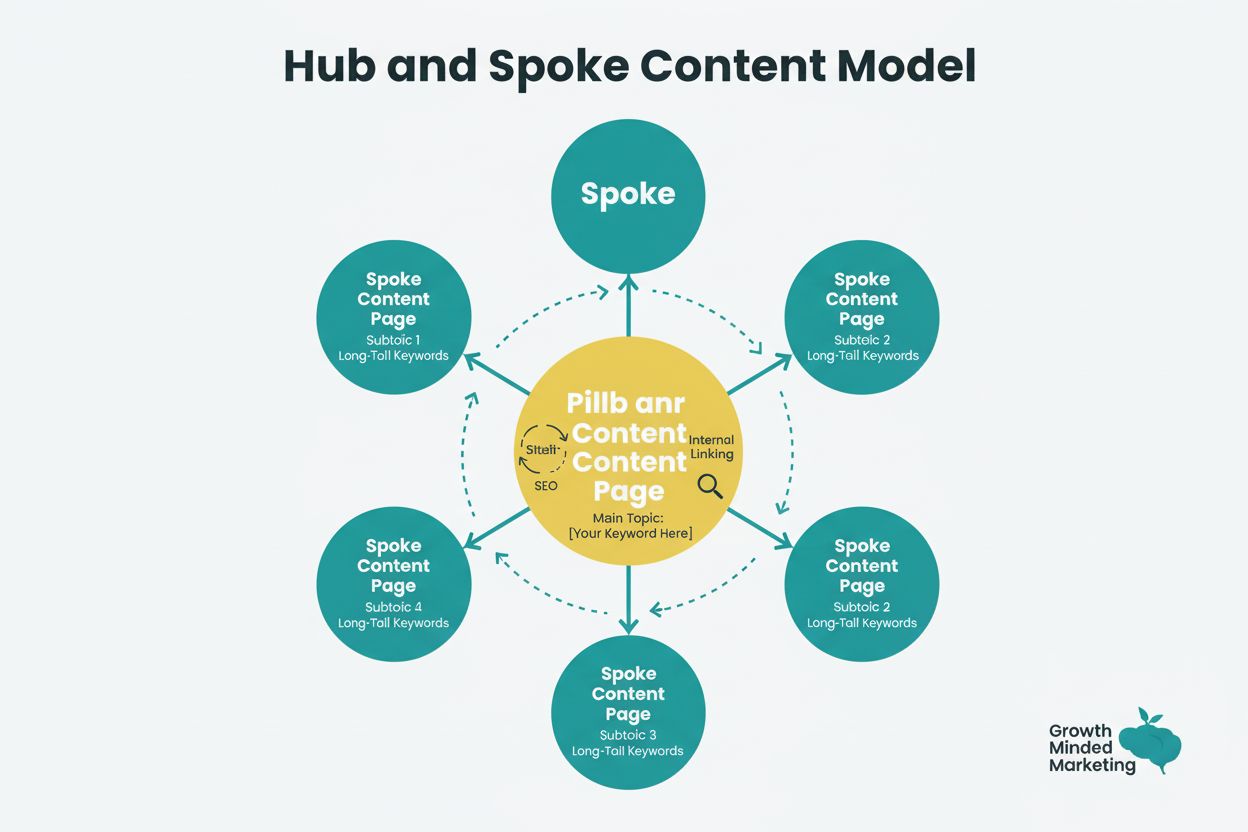

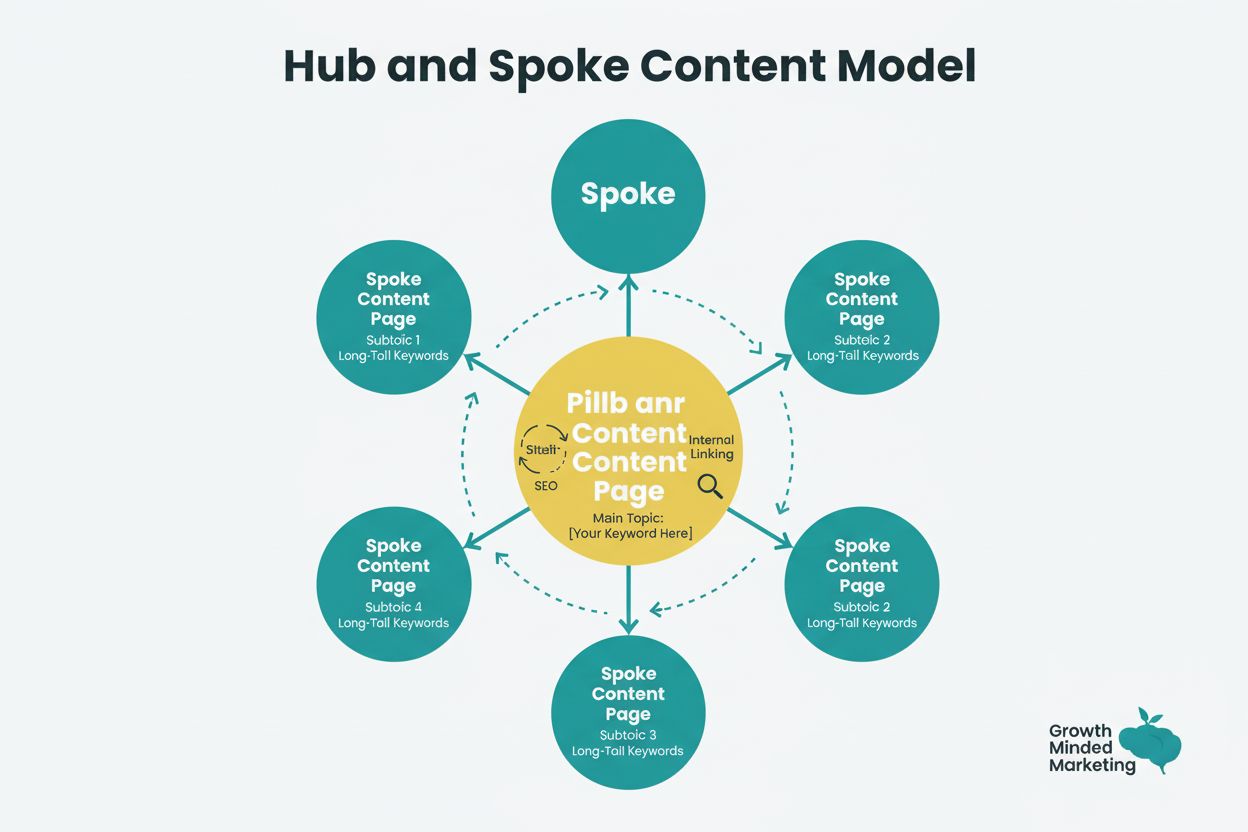

Hub and Spoke Model

Learn what the Hub and Spoke Model is, how it works for content architecture, and why it's essential for SEO authority, internal linking, and AI visibility moni...

Learn how the hub and spoke distribution model works, its benefits for logistics and supply chain management, and how it compares to point-to-point distribution systems.

The hub and spoke model is a centralized distribution system where goods are consolidated at a central hub location and then distributed outward to multiple regional spokes or fulfillment centers, optimizing delivery times and reducing logistics costs.

The hub and spoke model is a logistics and distribution strategy that mirrors the structure of a bicycle wheel, with a central hub serving as the primary consolidation point and multiple spokes radiating outward to regional distribution centers. This centralized approach to inventory management has become increasingly popular in modern supply chain operations, particularly for ecommerce businesses, retailers, and manufacturers seeking to optimize their distribution networks. The model fundamentally changes how goods move through the supply chain by eliminating direct point-to-point shipments in favor of a more coordinated, centralized system that improves efficiency and reduces operational complexity.

The hub and spoke distribution system operates through a clearly defined process that begins with inventory consolidation and ends with customer delivery. All incoming inventory from multiple suppliers is first directed to a single central hub location, where it undergoes receiving, quality checks, and processing. This hub is strategically positioned, often near major metropolitan areas or transportation hubs, to facilitate easier access for suppliers and faster distribution to regional centers. Once inventory arrives at the hub, it is sorted, organized, and then distributed to multiple regional spokes—which are fulfillment centers or distribution points located closer to end customers. From these spoke locations, the final mile delivery to customers is executed, ensuring products reach their destinations quickly and efficiently.

The key distinction between this model and traditional point-to-point distribution is significant. In point-to-point systems, suppliers ship directly to individual fulfillment centers or customers, creating a complex web of shipping routes that becomes increasingly difficult to manage as businesses scale. With the hub and spoke approach, suppliers only need to send inventory to one location, dramatically simplifying logistics coordination and reducing the number of shipping routes required. This consolidation at the hub allows for better inventory visibility, more efficient receiving operations, and the ability to strategically allocate products based on regional demand patterns.

| Benefit | Description | Impact |

|---|---|---|

| Cost Reduction | Consolidating shipments at a central hub enables bulk processing and more efficient routing | Significant savings on transportation and freight costs |

| Faster Delivery Times | Inventory positioned closer to customers through regional spokes | Reduced transit times and improved customer satisfaction |

| Improved Inventory Control | Centralized management of stock levels across all locations | Better demand forecasting and reduced overstocking |

| Scalability | Easy to add new spoke locations without overhauling the entire system | Flexible growth without major operational disruptions |

| Enhanced Visibility | Real-time tracking of inventory movement through the network | Better supply chain transparency and decision-making |

| Resource Optimization | Centralized receiving and processing operations | Reduced labor costs and more efficient warehouse operations |

The hub and spoke model delivers substantial advantages that directly impact a business’s bottom line and operational efficiency. One of the most compelling benefits is cost reduction, as consolidating shipments at a central hub allows businesses to negotiate better freight rates by combining less-than-truckload (LTL) shipments into full truckload (FTL) shipments. This consolidation strategy can reduce transportation costs by 20-40% compared to direct point-to-point shipping. Additionally, suppliers benefit from making a single delivery to the hub rather than multiple deliveries to various fulfillment centers, further reducing their transportation expenses and environmental impact.

Faster delivery times represent another critical advantage, particularly for ecommerce businesses competing in markets where two-day or next-day delivery has become the standard expectation. By positioning inventory at regional spokes closer to customer populations, businesses can dramatically reduce the time required for last-mile delivery. The hub’s strategic location near major transportation corridors also accelerates the initial receiving process, ensuring inventory enters the distribution network quickly. This combination of faster hub processing and proximity to customers through spokes creates a significant competitive advantage in delivery speed.

Improved inventory control and visibility emerge as essential benefits in today’s data-driven supply chain environment. With a centralized hub managing all incoming inventory, businesses gain unprecedented visibility into stock levels, product movement, and demand patterns across their entire network. This centralized oversight enables more accurate demand forecasting, allowing businesses to allocate inventory to spokes based on actual customer demand rather than guesswork. The result is reduced overstocking in some regions and understocking in others, leading to better inventory turnover and lower holding costs.

Scalability and flexibility make the hub and spoke model particularly attractive for growing businesses. Unlike rigid point-to-point systems that require significant restructuring to accommodate new markets or fulfillment locations, the hub and spoke approach allows businesses to add new spokes incrementally without disrupting existing operations. This flexibility enables companies to expand into new geographic markets, launch new sales channels, or adjust their distribution footprint in response to changing market conditions without incurring massive capital expenditures or operational overhauls.

Understanding the differences between these two distribution models is essential for businesses evaluating their logistics strategy. The point-to-point model represents the traditional approach where suppliers ship directly to individual fulfillment centers or customers. While this method appears simpler on the surface, it creates significant complexity as businesses scale. Consider a scenario where a business has three suppliers and five fulfillment centers: the point-to-point model requires 15 different shipping routes (3 suppliers × 5 centers). As the business grows and adds more suppliers or fulfillment centers, this number grows exponentially, creating a logistical nightmare of coordination, tracking, and cost management.

The hub and spoke model elegantly solves this complexity problem. Using the same scenario, suppliers only need to send inventory to one hub location, and that hub then distributes to the five fulfillment centers. This reduces the number of primary shipping routes from 15 to just 8 (3 suppliers to hub + 5 hub to centers), and more importantly, it centralizes all coordination and inventory management at a single location. As the business continues to scale, adding new suppliers or fulfillment centers becomes a simple matter of adding new routes to or from the hub, rather than creating exponentially more complex direct connections.

The point-to-point model does retain some advantages in specific scenarios. For businesses with a very limited number of distribution points, simple supply chains, or specialized shipments requiring direct routes, point-to-point distribution can offer simpler logistics and potentially faster direct shipments without intermediate handling. However, these advantages quickly disappear as businesses grow, making the hub and spoke model the preferred choice for most modern supply chains.

The hub and spoke distribution model has proven its effectiveness across multiple industries, each adapting the core concept to their specific operational needs. In the airline industry, major carriers use hub airports as consolidation points where passengers and cargo from multiple origin cities are collected, sorted, and redistributed to various destination cities. This approach allows airlines to operate more efficiently than if they maintained direct flights between every city pair. Similarly, in logistics and ecommerce, companies like Amazon have built their competitive advantage on sophisticated hub and spoke networks, with regional fulfillment centers positioned strategically across the country to enable fast delivery to customers.

The retail industry has embraced hub and spoke distribution to manage the complexity of supplying hundreds or thousands of store locations. Large retailers use regional distribution centers as hubs that receive inventory from multiple suppliers and manufacturers, then distribute products to individual stores based on local demand patterns. This centralized approach allows retailers to negotiate better supplier terms, maintain tighter inventory control, and respond quickly to regional market trends. Even smaller retailers increasingly adopt hub and spoke principles through third-party logistics providers, gaining access to the efficiency benefits that were previously available only to large enterprises.

While the hub and spoke model offers substantial benefits, businesses should be aware of potential challenges when implementing this distribution strategy. Higher inventory costs can emerge if inventory must be rotated among multiple locations or if safety stock levels need to be maintained at both hub and spoke locations. Additionally, the complexity of coordination between hub and spoke operations requires robust systems, clear communication protocols, and skilled personnel to manage effectively. Some businesses may experience slower response times to urgent customer needs if the distance between spokes and the hub creates delays in emergency restocking situations.

Fragmented customer service can occur if different regions receive products at different speeds due to varying distances from the hub or differences in spoke efficiency. Businesses must implement standardized processes and performance metrics across all spoke locations to ensure consistent customer experiences. Furthermore, if certain products are only available at specific spoke locations, customers in other regions may face unavailability issues, requiring careful inventory allocation strategies and demand forecasting to prevent such situations.

Successful implementation of a hub and spoke model requires careful planning and phased execution. Businesses should start with regional pilots, testing the model with a single hub and a few spokes before full-scale rollout. This approach allows organizations to validate processes, identify bottlenecks, and refine operations before committing significant resources. Leveraging real-time logistics tracking systems provides visibility across hub and spoke operations, enabling early identification of issues and data-driven optimization. Aligning inventory planning with fulfillment data ensures that restocking decisions at spokes are based on actual demand patterns rather than assumptions.

Incrementally expanding the network by adding spokes in phases allows confidence to build in the model before scaling to full capacity. Building strong coordination protocols between hub and spoke teams ensures everyone operates from the same playbook, with clear processes, reporting standards, and contingency plans. Finally, investing in technology infrastructure, including warehouse management systems (WMS), inventory management systems (IMS), and transportation management systems (TMS), provides the visibility and automation necessary to operate an efficient hub and spoke network.

The hub and spoke distribution model represents a fundamental shift in how modern businesses approach logistics and supply chain management. By centralizing inventory consolidation and strategically positioning regional distribution points, businesses can achieve significant cost savings, faster delivery times, improved inventory control, and greater scalability. While the model requires careful implementation and ongoing management, the benefits for growing businesses, retailers, and manufacturers far outweigh the challenges. As ecommerce continues to evolve and customer expectations for fast, reliable delivery continue to rise, the hub and spoke model has become not just an option but a necessity for businesses seeking to remain competitive in today’s dynamic marketplace.

Track how your brand, domain, and URLs appear in AI-generated answers across ChatGPT, Perplexity, and other AI search engines. Ensure your business maintains visibility in the AI-powered search landscape.

Learn what the Hub and Spoke Model is, how it works for content architecture, and why it's essential for SEO authority, internal linking, and AI visibility moni...

Community discussion on using the hub and spoke content model for AI visibility. Content strategists share experiences with topic clusters and pillar content fo...

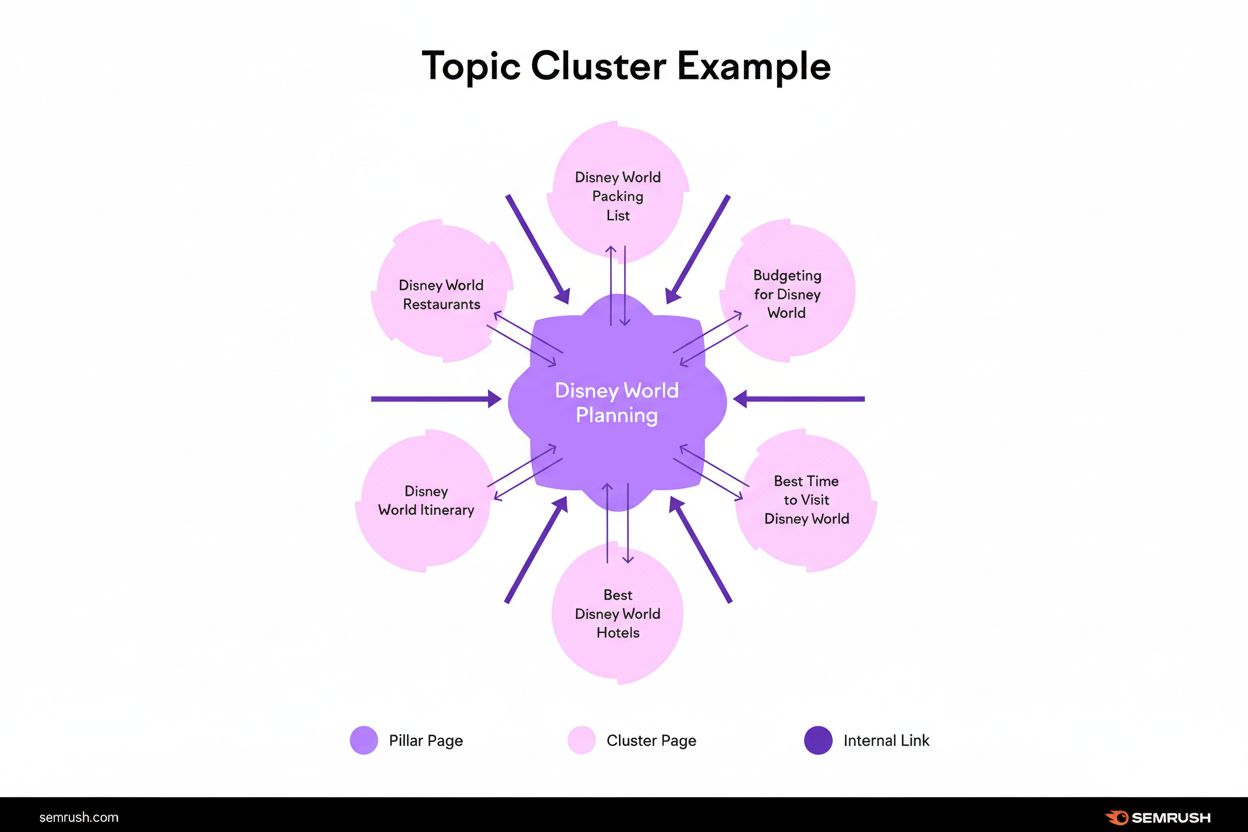

Learn what the Topic Cluster Model is, how it works for SEO, and why it matters for ranking in Google, ChatGPT, Perplexity, and other AI search platforms. Compl...